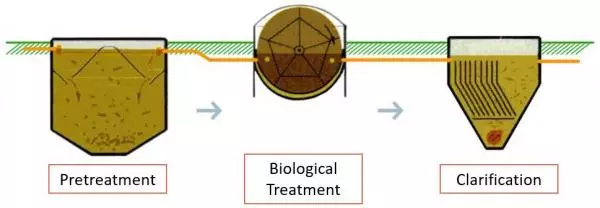

Pretreatment

The mechanical pretreatment of the raw wastewater represents the first stage of the process in all biological wastewater treatment plants. Coarse contaminants and undissolved organic substances are removed by sieves, coarse filters or by settling. Depending on the quality of the wastewater, the following pre-treatment processes can be used:

- Equipments : Screening / Strainer / Sand & Grease Removal Chamber

- Concrete structures : Primary Settler / Digester Settler / 3-Pit-chamber

Pretreatment facilities are not part of the standard PMT portfolio, but we can assist in the selection and design in most cases. The process choice in pretreatment affects also the biological stage.

Biological Treatment

Biological treatment is the phenomenon in which microorganisms degrade the pollution in the wastewater, represented by Carbon and Nutrients.

PMT technologies are biofilm processes, where the bacteria develop on a support media. Fixed biology brings an additional resilience against load variations, thus it provides a higher process realibility.

In the case of Ecodisk, bacteria develop on the rotating discs, forming a surface layer called biofilm. These bacteria absorb oxygen from the air as they emerge, and absorb the soluble pollution from the wastewater when they immerged. Following the absorbtion, the bacteria multiply their colony on the surface of biodiscs. The rotation of the discs is used to control the biofilm thickness. This gives a remarkable advantage to the Ecodisk system which can adjust its biology automatically in front of the changing pollution. The excess bacteria are detached from the surface layer by gravity and seperated as sludge by secondary clarifier.

In the case of the Ecosim and the MBBR Pack, bacteria develop on moving biofilm carriers.

In Ecosim, oxygen is provided to the system by rotational movement, like an Ecodisk.

In the MBBR Pack, oxygen is provided directly via a blower and a diffusion system in the bottom of the tank.

Secondary Clarification

The sludge generated during the main biological step will be seperated in the secondary clarification. PMT provides two related technologies for the clarification step; lamella separators or drum filters in combination with our Ecodisk and Ecosim.

Thanks to their simple, robust and efficient design, our DLE lamella separators are to operate. The optimized lamella placement and the compact design provide high settling surface in small volumes.

For more agressive design approaches, PMT has developed the EcodiskTM Filter, a standard biodisc solution with the usage of HydrotechTM drum filter pannels.